Let the customer be satisfied!

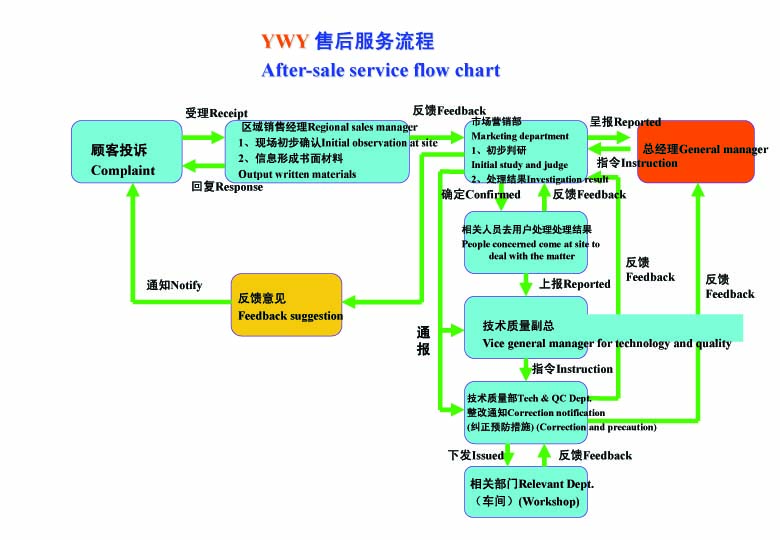

YWY pays great attention to pre-sale, sale and after-sale service. For us, we manage to do “knowing yourself and knowing your enemy”, and in the meanwhile let the customer learn before doing, so that to make the customer carefree and satisfactory. We have set offices in Shanghai, Changzhou, Beijing, Wuhan, Xi’an, Guangzhou, Chongqing in order to provide excellent products and service efficiently and at any time to our customers.

|

|

|

|

YWY has a complete quality control and testing system, including a testing laboratory center, which consists of a non-destructive testing room, a performance room, a material room, a chemistry room, a testing room and a testing base. The testing center and testing base do research, testing, measurement and processes 176 sets of equipment. The testing center can conduct metal material composition analysis, mechanical performance analysis, and microstructure testing; test and evaluate bearing noise, sealing, vibration, friction torque and other items; check the bearing's dimensional tolerance, shape tolerance, position accuracy, and surface roughness Inspection: The internationally advanced full-digital ultrasonic flaw detector and high-resolution fluorescent magnetic particle flaw detection equipment are used for non-destructive flaw detection of bearings.